Understanding Walk-In Cooler Installation Costs: What Every Business Owner Needs to Know

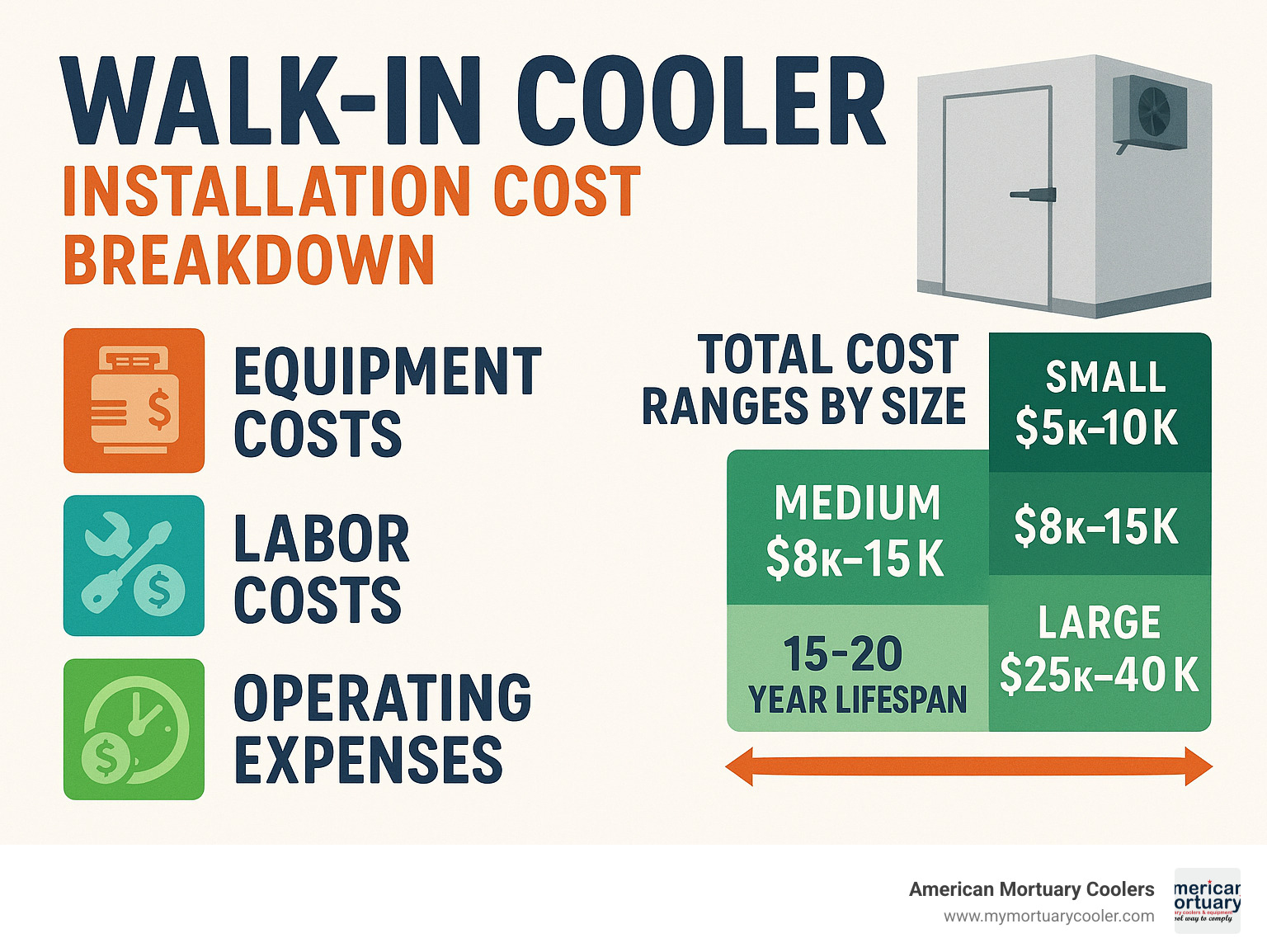

Walk in cooler installation cost typically ranges from $5,000 to $40,000 depending on size, features, and complexity. Here's what you need to budget for:

Quick Cost Breakdown:

- Small units (6×6): $5,000 - $10,000

- Medium units (8×10 to 10×10): $8,000 - $15,000

- Large units (20×20+): $25,000 - $40,000

- Cost per square foot: $100 - $150

- Installation labor: $2,000 - $7,000

- Monthly operating costs: $100 - $500

Walk-in coolers are essential refrigeration systems that maintain consistent temperatures between 35°F and 41°F. They're used across industries - from restaurants storing perishable ingredients to funeral homes preserving dignity in their most important work.

The total investment goes beyond the initial purchase price. You'll need to factor in panels, refrigeration systems, flooring, electrical work, and ongoing maintenance costs over the unit's 15-20 year lifespan.

Getting the sizing right matters. A 6×6 unit costs about $65 monthly to operate, while an oversized 8×12 unit jumps to $117 monthly. The refrigeration system alone represents 30-40% of your total project cost.

Why location affects pricing: Indoor installations may require structural modifications, while outdoor units need concrete slabs and weatherproofing. Regional labor rates also vary significantly - installation in New York averages $9,638 compared to $5,839 in Seattle.

We're American Mortuary Coolers, a Tennessee-based manufacturer specializing in custom mortuary coolers and related equipment. Our experience helping funeral directors and businesses across the contiguous 48 states steer walk in cooler installation cost gives us unique insight into what drives pricing and how to optimize your investment.

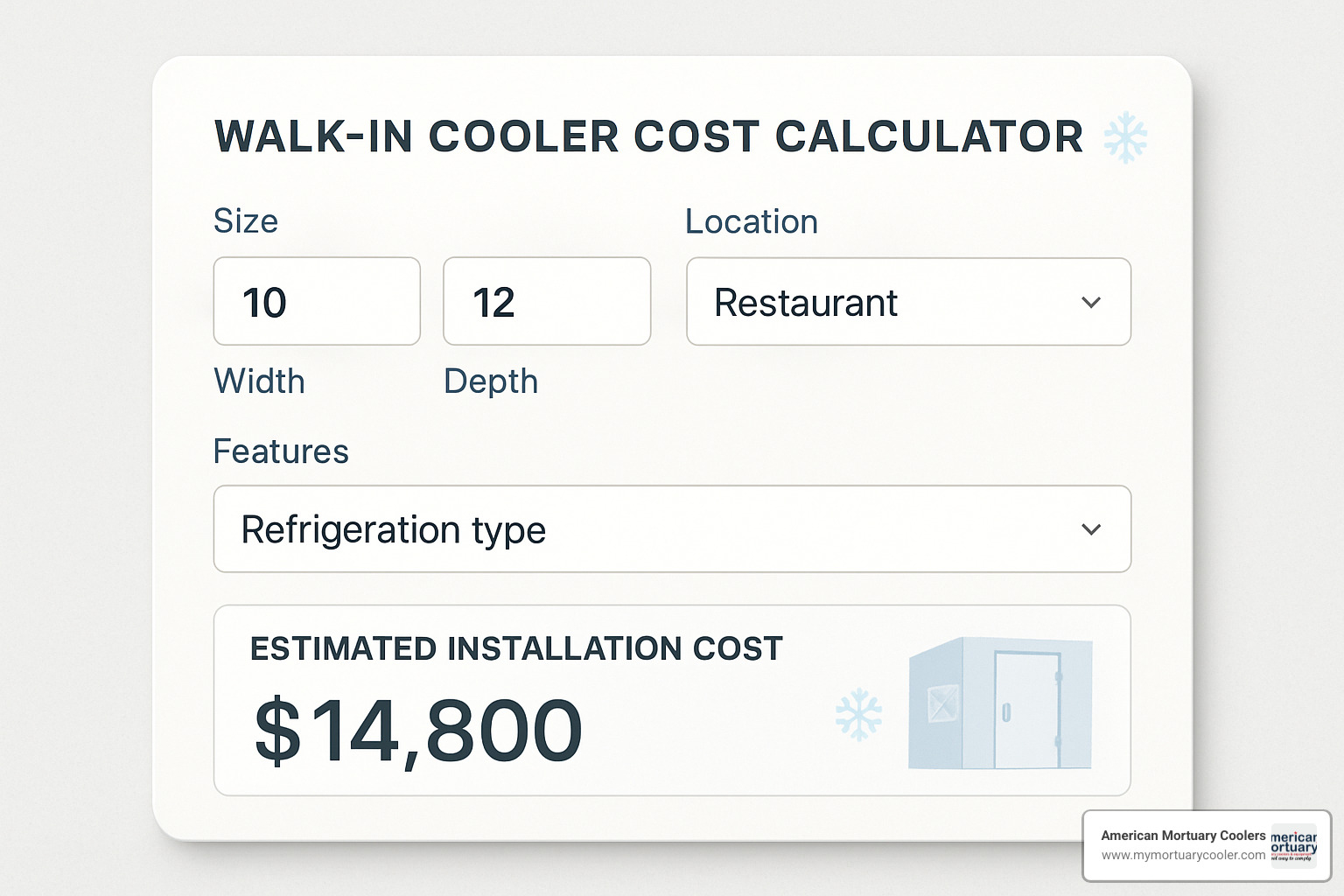

Walk-In Cooler Installation Cost Calculator

Let's get real about walk in cooler installation cost - it's not just about the sticker price. You're looking at anywhere from $5,000 to $40,000, but the devil's in the details.

Think of it like buying a car. A basic sedan gets you from point A to B, but add leather seats, a sunroof, and all-wheel drive, and suddenly you're in different territory. Walk-in coolers work the same way.

The smartest way to budget? Cost per square foot. Most installations run $100 to $150 per square foot. This covers your panels, insulation, and basic refrigeration - but not the labor or fancy extras.

Here's where geography gets interesting. That same cooler costs wildly different amounts depending on where you live. A 10-square-foot unit might cost $9,638 in New York but only $5,839 in Seattle. Why? Labor rates, permits, and how easy it is to get materials to your site.

Urban areas typically run 20-40% higher than suburban locations. It's not just the higher wages - city building codes are stricter, parking for delivery trucks costs more, and everything takes longer when you're working around other businesses.

If you want to dive deeper into the technical side, check out this scientific research on cooling systems. And when you're ready to get serious about pricing, our detailed guide to walk-in cooler quotes walks you through exactly what to ask for.

Average Walk In Cooler Installation Cost by Size

Size matters - a lot. But it's not just about square footage. Walk in cooler installation cost jumps in chunks, not smooth curves.

Small units at 6×6 feet run $5,000 to $10,000. These are perfect for small cafes or specialty shops. You get about 36 square feet of actual storage space (the interior dimensions are 6'3" × 6'3" × 8'H). They're efficient, but you pay more per square foot because certain costs - like the door and basic refrigeration - stay the same regardless of size.

Step up to 8×10 feet and you're looking at around $12,000. This is the sweet spot for many restaurants. With 81 square feet of storage space, you get room to organize properly. Our data shows these units average $11,709 for the cooler itself, plus another $500 for a half-horsepower refrigeration system.

The popular 10×10 size hits that $8,000 to $15,000 range. With 100 square feet, you've got serious storage capacity. This size works well for mid-sized restaurants, catering companies, or funeral homes that need reliable temperature control.

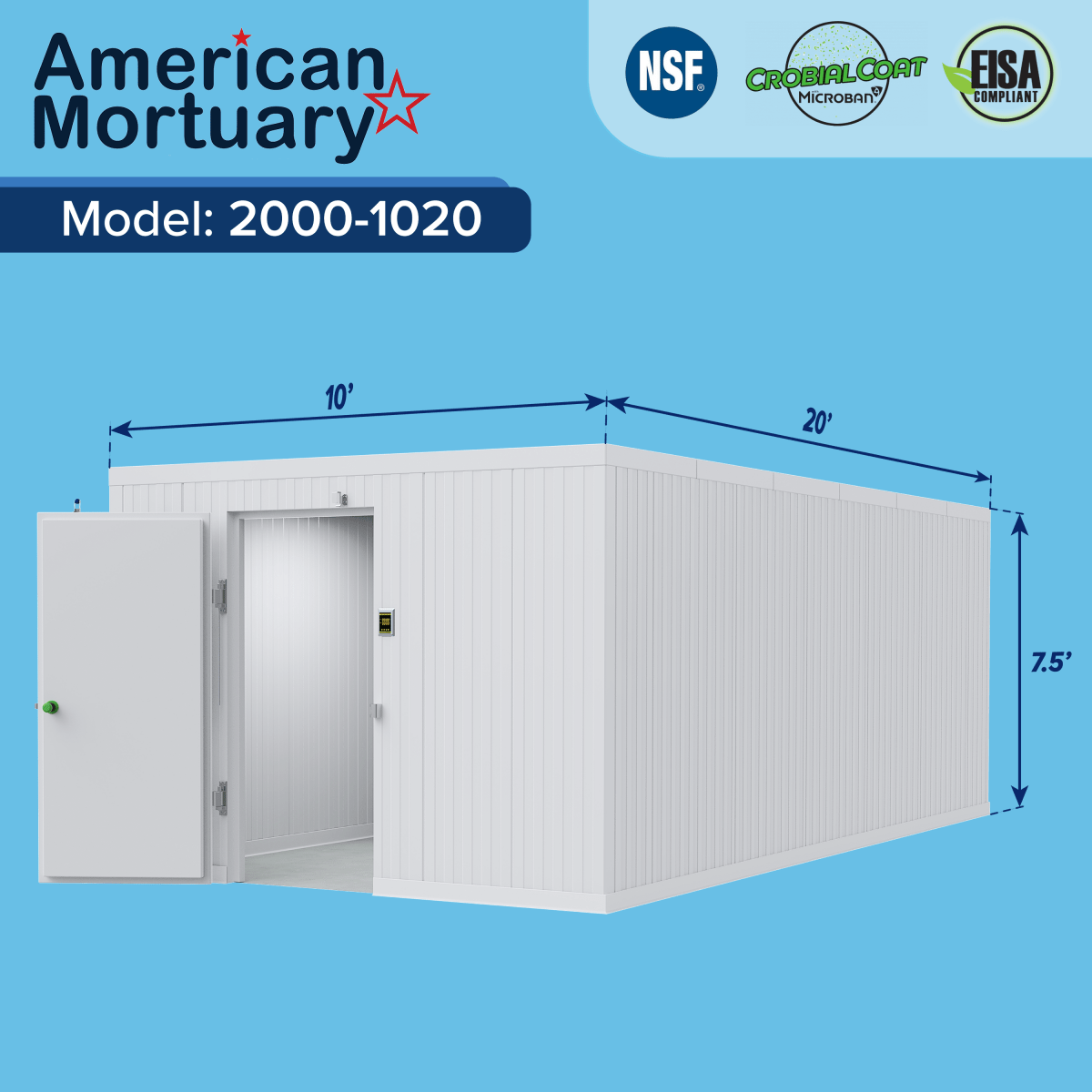

Large units starting at 20×20 jump to $25,000 to $40,000. These are for serious operations - big restaurants, food distributors, or facilities that need industrial-grade storage. Custom configurations can push past $45,000 when you add specialized features.

Indoor versus outdoor installation changes everything. Indoor units might need structural work, electrical upgrades, or ventilation improvements. Outdoor units need concrete slabs, weatherproofing (which adds 10-15% to your base cost), and proper drainage. Sometimes outdoor saves money on building modifications, but you'll pay for site prep instead.

Walk In Cooler Installation Cost per Square Foot

Here's your magic number for quick estimates: $100 to $150 per square foot. This is how contractors think, and it's how you should budget.

But like any rule, there are exceptions. Budget installations might hit $80 to $100 per square foot if you keep things simple. Premium setups with all the bells and whistles can push $150 to $200 or more.

This covers your panels, insulation, and basic refrigeration. It doesn't include the labor ($2,000 to $7,000), site prep, electrical work, permits, or delivery. Think of it as the equipment cost, not the total project cost.

Smaller units cost more per square foot - that's just math. A door costs the same whether it's on a 6×6 or 10×10 unit. Same with the basic refrigeration system and labor minimums.

Lifetime Operating & Maintenance Costs

The sticker shock doesn't end at installation. Your walk in cooler installation cost is just the beginning of a 15-20 year relationship.

Monthly operating costs run $100 to $500, depending on your setup. A small 6×6 unit might cost around $65 monthly to run. Step up to an 8×12 unit and you're looking at $117 monthly for cooling - but if you need freezer temperatures, that same unit jumps to $372 monthly.

Maintenance isn't optional. Budget $150 to $500 annually for preventive care - cleaning coils, checking seals, calibrating controls. Skip this and you'll pay $200 to $1,000+ when something breaks at the worst possible moment.

Your operating costs depend on several factors: insulation quality (better insulation pays for itself), door seals (worn gaskets are energy vampires), system efficiency (newer units run cheaper), and how often you open the door (every opening costs money).

Most units run 16-18 hours daily and last 15-20 years with proper care. At current commercial electricity rates averaging $0.0999 per kWh, factor these ongoing costs into your total investment. The cheapest unit upfront might cost more over its lifetime if it's inefficient.

Component & Labor Cost Breakdown

When you're planning your walk in cooler installation cost, it helps to understand what you're actually paying for. Think of it like buying a car - you want to know whether you're paying for the engine, the fancy wheels, or just the dealer markup.

The refrigeration system typically eats up the biggest chunk of your budget at 30-40% of total cost. That's followed by the panels and insulation at 25-35%, then installation labor at 20-30%. The remaining costs split between flooring (10-15%) and doors with accessories (5-10%).

This breakdown matters because it shows you where you can potentially save money and where cutting corners might hurt you later. The refrigeration system isn't where you want to go cheap - it's literally the heart of your cooler.

Panels & Insulation

Your cooler panels do the heavy lifting when it comes to keeping things cold. They're not just walls - they're engineered insulation systems that can make or break your energy bills. Expect to pay $50 to $100 per linear foot for standard 4-inch thickness panels.

You've got two main insulation choices, and honestly, both have their fans. Polyurethane foam gives you excellent initial performance with an R-value around 32, but it can degrade over time. Extruded polystyrene stays more stable long-term and handles moisture better, which matters if you're in a humid climate.

Most businesses go with 4-inch panels (R-value around 25) because they handle typical applications just fine. But if you're dealing with extreme temperature differences or want to maximize energy efficiency, 6-inch panels give you that extra insulation boost.

The shell panels themselves run $8 to $25 per square meter, and they come with a cam-lock assembly system that makes installation much easier. Standard white finish works for most applications, but premium finishes will bump your costs up by 10-40%. The good news? These panels typically come with a 10-year warranty and NSF/ANSI 7 approval for food-grade applications.

Refrigeration System Options

Here's where your walk in cooler installation cost can really vary. Refrigeration systems range from $2,000 to over $11,000, and the type you choose depends on your space and cooling needs.

Self-contained units ($1,400 to $4,000) are like the compact cars of refrigeration. Everything's in one package, installation is straightforward, and they work great for smaller applications. Think of them as plug-and-play solutions.

Remote systems ($5,000 to $11,000+) are more like pickup trucks - they cost more upfront but handle bigger jobs better. You get a separate indoor evaporator and outdoor condensing unit, which means higher capacity and better efficiency. The trade-off? More complex installation with refrigerant lines to run.

Your horsepower needs can range from a modest 0.5 HP for small units up to 5+ HP for large installations. An 8×10 unit typically needs about 7,020 BTUH of refrigeration capacity and uses roughly 0.1529 kWh per day. All equipment must be EISA-compliant to meet federal regulations.

Flooring, Doors & Lighting

Insulated flooring runs $6 to $15 per square foot, and while it might seem like an expensive add-on, it prevents condensation and thermal bridging that can cause real headaches later. You can skip the floor if your existing surface meets requirements, which saves 10-20% of costs. Just make sure it can handle heavy cart traffic if that's part of your operation.

Door selection affects both cost and daily operation. Standard hinged doors with 36" × 78" openings work for most applications, but wider 49" doors make loading much easier if you're moving large items. Automatic door closers are worth the investment - they help maintain temperature when staff gets busy and forgets to close doors properly.

LED lighting costs $30 to $60 per bulb but pays for itself through energy savings and reduced maintenance. Good lighting isn't just about seeing what you're doing - it's a safety issue when people are working in tight, cold spaces.

Strip curtains reduce heat gain during loading, thermometers help you stay compliant with temperature requirements, and proper shelving maximizes your storage efficiency. Alarm systems can alert you to temperature problems before you lose valuable inventory.

Installation Labor & Site Prep

Professional installation isn't optional if you want your cooler to work properly and maintain warranty coverage. Labor costs typically run $2,000 to $7,000, depending on how complex your installation gets.

You'll need several different trades involved. HVAC technicians handle refrigeration connections, electricians wire power and controls, general contractors prep the site, and plumbers may be needed for condensation drainage. Getting all these trades coordinated is part of what you're paying for.

Site preparation requirements can't be skipped. You need a level installation surface (this is critical for proper assembly), adequate electrical service (usually 208-230V), proper ventilation around condensing units, and drainage for condensation lines. Outdoor installations also need concrete slabs.

| Installation Type | Labor Cost Range | Additional Requirements |

|---|---|---|

| Indoor | $2,000 - $5,000 | Structural modifications, ventilation |

| Outdoor (Protected) | $2,500 - $6,000 | Concrete slab, weatherproofing |

| Outdoor (Freestanding) | $3,000 - $7,000 | Full weather protection, improved foundations |

Complex installations requiring major electrical upgrades, structural modifications, or custom configurations can push costs beyond these ranges. That's why getting a detailed site assessment upfront helps avoid surprises in your walk in cooler installation cost.

Price Drivers, Pitfalls & Money-Saving Strategies

Nobody likes sticker shock, especially when you're already dealing with the stress of getting a new cooling system installed. The good news? Understanding what drives walk in cooler installation cost helps you budget smartly and avoid those painful surprises that can derail your project.

The biggest price drivers aren't always obvious. Size matters, but geographic location can swing your costs by thousands. A project that costs $15,000 in Atlanta might hit $22,000 in New York City - same cooler, different zip code.

Building code requirements vary wildly between jurisdictions. Some areas have strict ventilation rules, others require specific electrical setups. Site accessibility matters too - if installers need to crane equipment over a building or work around tight spaces, expect higher labor costs.

Timeline pressure is expensive. Rush orders typically add 15-25% to your total cost. Custom features and premium finishes look great but can push a standard $12,000 installation to $18,000 or more.

The smartest business owners plan ahead and understand these variables before getting quotes. For a deep dive into what affects pricing, check out our detailed guide on decoding walk-in cooler pricing factors.

Location, Permits & Utility Upgrades

Location affects your walk in cooler installation cost more than most people realize. It's not just about labor rates - though those vary dramatically. Northeast installations typically run 20-40% above national averages, while West Coast projects add 15-30% premiums. The Southeast often comes in 5-15% below average, making it a sweet spot for value.

Permit costs seem small until they're not. Building permits range from $200 in small towns to over $1,000 in major cities. Electrical permits add another $100-$500. Food service businesses need health department approvals. Larger installations might require fire department reviews.

Here's where many projects get expensive fast: utility upgrades. Your existing electrical panel might not handle the additional load. Panel upgrades cost $1,500-$4,000. Installing dedicated circuits adds $300-$800. Ventilation improvements can hit $500-$2,000.

Condensation drainage sounds minor but matters. If your site lacks proper drainage, plumbing work adds $200-$600. Indoor installations often need ventilation upgrades to handle heat from condensing units.

Smart planning means getting your electrical system evaluated early. Many contractors offer free assessments that can prevent costly surprises later.

Standard vs Custom, Indoor vs Outdoor Boxes

The standard versus custom decision significantly impacts both cost and timeline. Quick-ship units arrive in 1-6 weeks and cost $8,000-$30,000 for most applications. You're choosing from proven configurations with limited customization options.

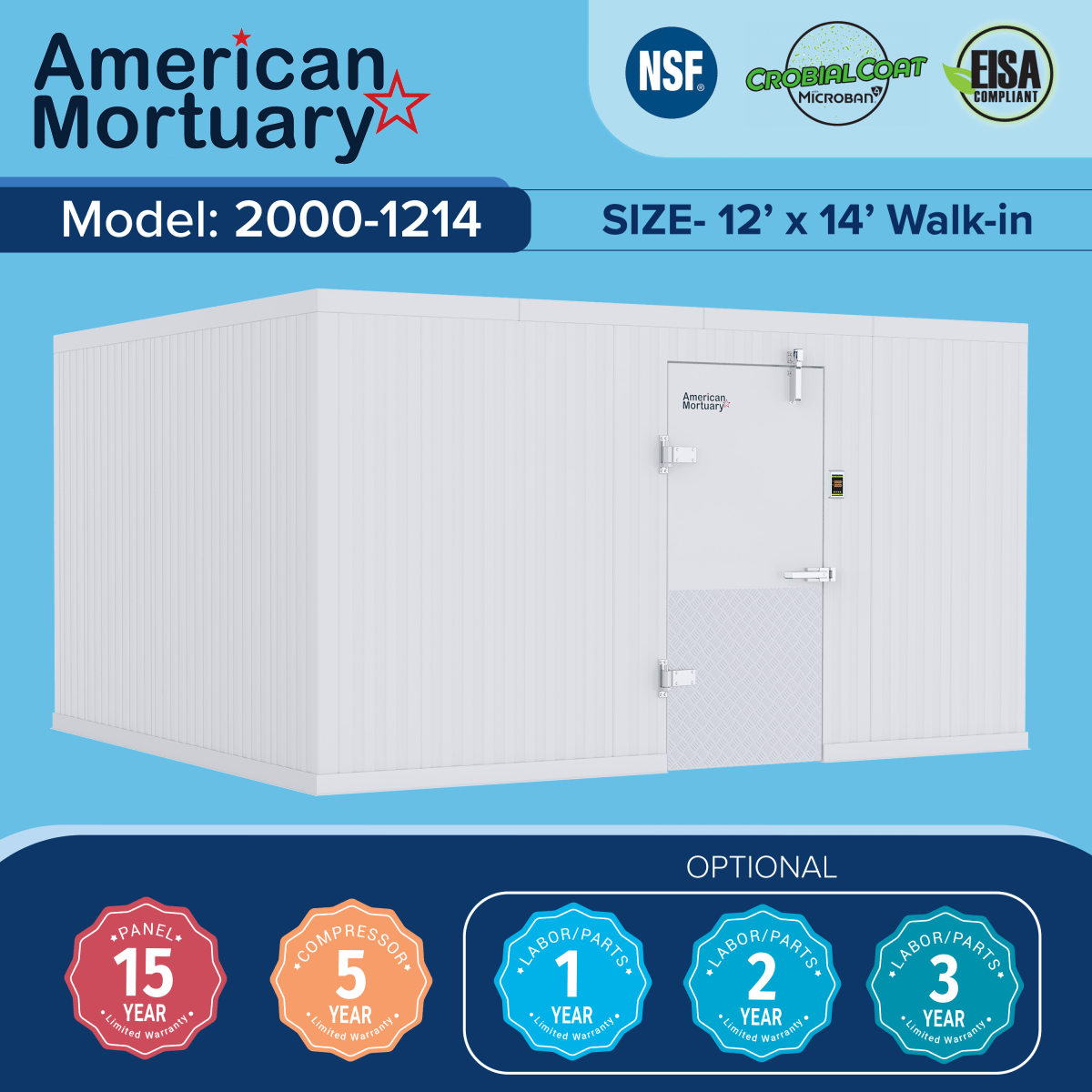

Custom units take 10-12 weeks but give you exactly what you need. Costs range from $10,000-$40,000+ depending on specifications. We build custom mortuary coolers regularly, and the precision matters for specialized applications.

Indoor installations seem simpler but often require structural modifications. You might need reinforcement for floor loading, ventilation planning, and integration with existing systems. Access for delivery and assembly can be challenging in tight spaces.

Outdoor installations need concrete slabs and weatherproofing packages that add 10-15% to base costs. However, you avoid building modifications and often get easier access for maintenance. Proper site grading and drainage prevent future problems.

The decision often comes down to your building's constraints and long-term plans. Outdoor units offer flexibility but need protection from weather extremes.

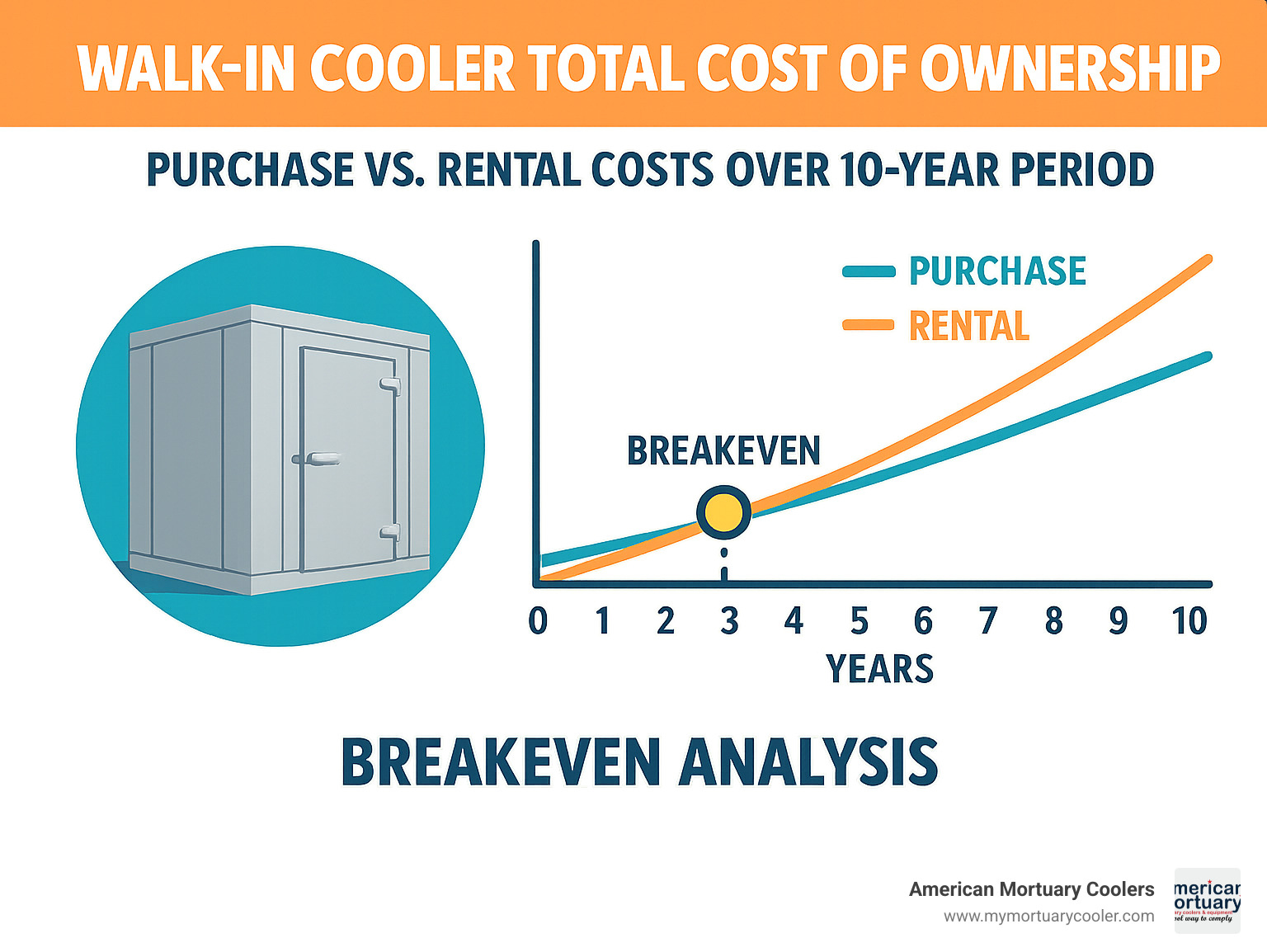

Buy vs Rent vs Lease – ROI Analysis

The buy versus rent decision affects your cash flow and long-term costs significantly. Purchasing requires $10,000-$20,000+ upfront plus $2,000-$5,000 installation costs. You'll spend $500-$1,000 annually on maintenance over the unit's 15-20 year lifespan.

Rental costs run $300-$600 monthly and include delivery, setup, and maintenance. No upfront investment, but you're paying continuously without building equity.

Buying makes sense for permanent operations. You get asset ownership, depreciation benefits, complete control over specifications, and no ongoing rental payments. The downsides? High upfront capital requirements, maintenance responsibility, and permanent commitment.

Renting works better for temporary needs or cash-flow management. Low upfront costs, included maintenance, and flexibility for changing requirements. The trade-offs are higher long-term costs, limited customization, and no asset ownership.

Most established businesses buy, while startups or seasonal operations often rent. Calculate your break-even point - typically 3-5 years depending on unit size and rental rates.

Cost-Saving Tips & Incentives

Right-sizing your cooler saves money upfront and long-term. Avoid the "bigger is better" trap - oversized units cost more to buy, install, and operate. Calculate your actual storage needs, not worst-case scenarios. A properly sized unit runs more efficiently and lasts longer.

Energy efficiency pays dividends. ENERGY STAR qualified equipment costs more initially but reduces operating costs significantly. High-performance insulation, LED lighting, and automatic door closers all improve efficiency. Strip curtains for loading areas prevent cold air loss.

Configuration choices impact costs substantially. Combo cooler/freezer units save 10-15% compared to separate units. No-floor options save 10-20% when your existing floor meets requirements. Standard sizes cost less than custom configurations.

Quick-ship models reduce delivery costs and get you operational faster. Sometimes the standard size that's close to your needs works better than a custom solution.

Financing and incentives can reduce your effective cost. Equipment financing spreads payments over time. Energy efficiency rebates from utilities offset premium equipment costs. Tax depreciation benefits help with cash flow. Some federal tax credits apply to qualifying energy-efficient equipment.

We've helped funeral homes across the country optimize their cooling investments. The key is balancing upfront costs with long-term value while meeting your specific operational needs.

Frequently Asked Questions about Walk-In Cooler Installation Cost

We get a lot of questions about walk in cooler installation cost from business owners who want to make smart investments. Here are the most common concerns we hear and the straight answers you need.

What is the typical walk in cooler installation cost for a restaurant?

Most restaurants spend between $8,000 and $15,000 for a properly sized walk-in cooler. This typically covers a medium-sized unit (8×10 to 10×10 feet) that handles the storage needs of most commercial kitchens.

Here's how that breaks down: You're looking at $6,000 to $10,000 for the equipment itself, another $2,000 to $5,000 for professional installation, and $500 to $1,500 for permits and any electrical work that's needed.

The final walk in cooler installation cost really depends on your specific situation. If you're installing indoors in an existing kitchen, you might need extra ventilation or structural changes. Your electrical panel might need upgrading too - older buildings sometimes can't handle the power requirements.

We've seen restaurant owners try to cut corners on sizing, but that usually backfires. A unit that's too small means constant restocking headaches, while oversizing wastes energy and money every month.

How does energy efficiency affect my walk in cooler installation cost?

Energy-efficient features will bump up your upfront costs by about 10-20%, but they pay for themselves pretty quickly through lower operating costs.

The premium you'll pay upfront includes $1,000 to $3,000 for high-efficiency refrigeration equipment, $500 to $1,500 for better insulation, and $200 to $500 for LED lighting systems. It seems like a lot, but stick with us here.

Those efficiency upgrades typically cut your monthly energy costs by 20-30%. Your equipment also lasts longer and needs fewer repairs. Plus, many utility companies offer rebates of $500 to $2,000 for qualifying energy-efficient equipment.

Let's put some real numbers on this: A standard 6×6 unit costs about $65 monthly to operate, while a high-efficiency model might only cost $45 monthly. That's $240 in savings every year - and energy costs aren't getting cheaper.

Should I DIY or hire professionals for walk in cooler installation?

We strongly recommend professional installation, and here's why: walk in cooler installation cost for labor might seem steep at $2,000 to $7,000, but trying to DIY this can cost you way more in the long run.

First off, refrigeration work requires EPA certification - it's not just recommended, it's the law. The refrigerants used in these systems can be dangerous if handled improperly. Most electrical work needs a licensed electrician too, especially for the power requirements these units need.

Then there's the warranty issue. Most manufacturers will void your warranty if the installation isn't done by certified professionals. When you're investing $10,000 to $20,000 in equipment, you don't want to lose warranty protection over trying to save on installation.

Professional installers also handle all the code compliance and permit issues. Health departments are particularly strict about commercial refrigeration - a rejected installation can shut down your operation until it's fixed properly.

The installation cost might seem like a lot, but it's actually a small fraction of your total investment. More importantly, proper installation ensures your cooler runs efficiently for its full 15-20 year lifespan. That professional setup pays for itself through reliable operation and energy savings.

For more detailed information about cooler features and their impact on pricing, visit our complete guide to walk-in cooler features and prices.

Conclusion

Making the right choice about walk in cooler installation cost is really about understanding the full picture - not just what you'll pay upfront, but what your investment will mean for your business over the next 15-20 years.

The numbers tell an important story. Whether you're looking at a compact $5,000 unit for a small café or investing $40,000+ in a large custom installation, you're making a decision that will impact your operations for decades. That $100-$150 per square foot for equipment, plus the $2,000-$7,000 for professional installation, represents the foundation of reliable refrigeration that keeps your business running smoothly.

The ongoing costs matter just as much. Those monthly operating expenses of $100-$500 and annual maintenance costs of $150-$500 aren't just line items on your budget - they're investments in keeping your products safe and your customers satisfied. A well-maintained walk-in cooler that runs efficiently saves you money every single month.

We've seen too many businesses make costly mistakes that could have been easily avoided. Don't oversize your unit - that bigger cooler might seem like a good idea, but it'll cost you more upfront and every month afterward. Plan ahead for electrical upgrades and site preparation, because these "surprise" costs can add thousands to your project. Get quotes from multiple qualified contractors, and remember that the cheapest bid isn't always the best value.

Professional installation isn't optional - it's essential for warranty coverage, code compliance, and optimal performance. Those energy-efficient features that cost a bit more today will pay for themselves through lower operating costs and longer equipment life.

At American Mortuary Coolers, we've been helping businesses across the contiguous 48 states steer these decisions for years. From our base in Tennessee, we deliver custom solutions whether you're in Atlanta, Chicago, or anywhere in between. We understand that reliable refrigeration isn't just equipment - it's peace of mind for your business operations.

The funeral industry has taught us that some things simply can't fail. That same commitment to reliability and quality drives everything we do, whether we're crafting a specialized mortuary cooler or helping a restaurant choose the right walk-in unit.

For more information about our products and services, visit American Mortuary Coolers or contact us directly to discuss your specific needs.

Remember: A well-planned walk-in cooler installation is an investment in your business's future. Take time to understand all costs involved, work with qualified professionals, and choose equipment that will serve you reliably for decades to come.